Prowinch is a UL 508A / File No. E524056 Certified Industrial Control Panel (ICPs) manufacturer for United States and Canada with in-house electrical engineers and designers specialized in most types of Cranes, Winches and Hoists controllers offering Complete turnkey solutions and products with multiple optionals to meet applicable UL safety requirements. All our UL508A Control Panels are assembled and tested by Prowinch in our Certified Facility in Miami, USA.

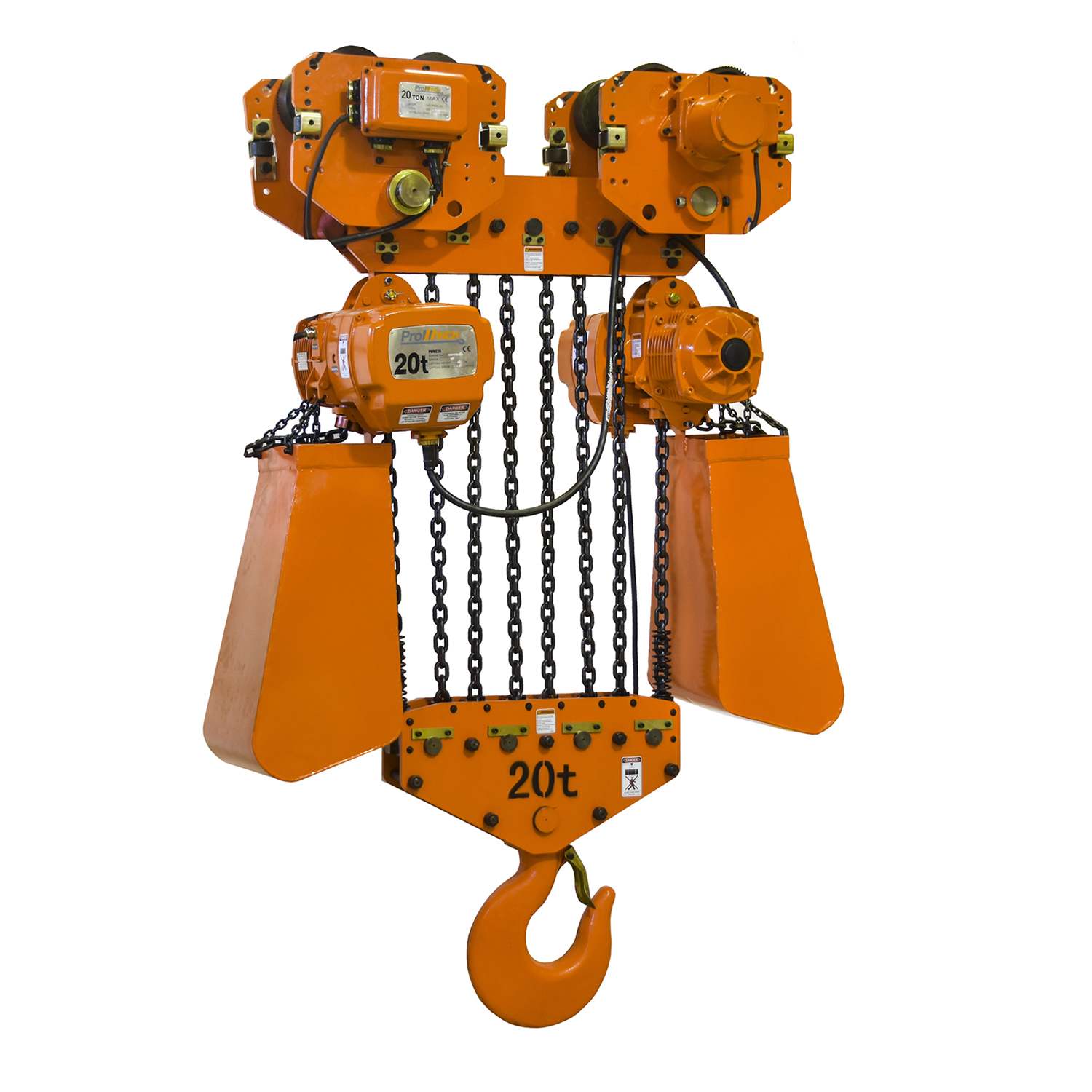

20 Ton Electric 1 speed Chain Hoist, 2 speed Power Trolley 40 ft. G100 Chain M4/H3 220~240/460V

$15,074.77 USD & Free Shipping to commercial locations with dock or forklift

Key features

- 3-year warranty, customer support, and service in the USA

- US Brand EATON Contactors, All ways Limit Switches, Emergency Stop

- Super Heavy Duty G100 Chain, 25% Stronger than G80. Standard ASTM A973

- US and EC Standards ASME HST-1 , ASME B30.16 , EN14492-2 , EN60204-32

- 3 Year Warranty, Customer Support and Service in the USA

Electric Chain Hoist Description

20 Ton Wireless Electric Chain Hoists are used for raising and lowering material. Power Cord is standard at 3 ft. for Hook and Push Trolley Mounts. Power Cord is standard at 3 ft. for Motorized Trolley Mounts. Hoists usually ship within 1-3 business days after ordering. Please call us at 1 (800) 971-8061 for any special requests. The Highest Quality, most Technologically Advanced Hoist in the Industry. Our hoist ranges from basic Light Duty H1 to Heavy Duty Motor - 60 minute, H4 classification, Class F insulation with cooling fins and standard thermal motor protection. Compact lightweight body offers one of the lowest headroom hoists in the industry. Extremely durable and reliable Pull Rotor Motor Brake. Contains NO brake coil to fail like conventional disc brakes. Durable Push-Button Pendant for easy, one-handed operation. Includes strain relief wire molded to pendant cord for added support and reliability. Quick Connectors save valuable time on setup and maintenance. “Quick disconnect” replaces typical competitive hard-wired designs. Easy Maintenance Control Panel is hinged to swing out to provide fast, easy, and trouble-free access. Completely Sealed Body suitable for both indoor and outdoor applications, including harsh environments. Gaskets throughout the hoist provide an IP55 rating. Oil Bath and precision machined helical and spur gears provide for quiet, smooth, and cool operations. Superior Quality Chain is precision gauged, Grade 100, manganese alloy load chain that is heat treated for wear resistance and extended life.

Prowinch Two Speed Electric Chain Hoist with Power Trolley

All of our Electric Chain Hoists are created with the goal of offering the best price–performance ratio. Key components such as lifespan factors are constantly tested and improved in order to offer the best product for the price.Key Components

All internal components have been upgraded to meet the highest quality standards. Key electronic components are produced by American or German brands, and we use American-made lubricants to ensure the lifespan of gears and reducers. Final assembly and all tests are performed in the US before shipping to ensure that every unit meets the corresponding standard.Duty Classification

Duty classification is a key factor when choosing the right unit. These H3 hoists are suitable for general machine shop fabricating, assembly, storage, and warehousing. For uniformly distributed work periods, the hoists have 25% max. operational time per hour and can handle up to 150 starts per hour. When being used for infrequent work periods, the hoist can be operated for 30 minutes from a cold start with up to 200 starts per hour. Operational time ratings are calculated at a 65% load factor, as per ASME HST-1-2012.Control System

This electric chain hoist comes standard with a pendant control. The length of the control is 4 feet less than the lifting height, which allows it to be easily operated from ground-level. An optional wireless control is available for extra convenience.Braking System

The electromagnetic brake system is tested at 125% of the hoist capacity and is designed to automatically engage immediately upon any loss of power.- Rated Load Capacity 44000 lb / 20000 kg

- Emergency Stop Yes

- Standard Lifting Height 40 ft / 12 m

- Contactor EATON 25 AMP

-

Speed (f/m) / min

4.6ft/1.4m@60Hz

3.8ft/1.2m@50Hz - Transmission / Reducer Type Spur gearbox with Oil splash lubrication

- Number of Speeds 1 Speed

- Load Chain Type G100

- Capacity Range 9

- Load Chain Size 11.2 x 34 mm

- Voltage 3 Phase 208~240/440~480V 50/60Hz

- Chain Falls 8

- USA and Canada Voltage 208~240/440~480V

- Chain Length 320 ft / 97 m

- Available Voltages 208~240/440~480V for USA and 380/440~480V for CHILE

- Humidity <85%

- Duty Class H3/M4/1Am/Class C

- Temperature -4 ~ 104° F / -20 ~ 40° C

- Motor/Engine Power 3.0 kW x 2

- Trolley Power 0.8 kW x 2

- Motor AMP 20 / 10

- Noise Level 81 dB

- Motor RPM 1728@60Hz 1440@50HZ

- Trolley Speed /min 36 ft / 11 m

- Motor Brake Yes

- Trolley Number of Speeds 1

- Insulation Grade F

- I-Beam Width Range 100-178 mm

- IEC Motor Protection IP55

- Standards Compliance ASME HST-1 , ASME B30.16 , B30.17 , EN60204-32

- Control Pendant Control and Optional Wireless

- Warranty 3 Year

- Control Voltage 24V

Unit Weight & Dimensions

- T Trolley Motor Width 9.09 in / 231 mm

- D Depth 50 in / 1260 mm

- R Trolley Cover Width 5.5 in / 142 mm

- W Width 25 in / 630 mm

- H Minimum Headroom 58 in / 1470 mm

- Total Unit Weight 2123 lbs / 964 Kg

Packaging Weight & Dimensions

- Package 1 Net Weight 2123 lbs / 963 Kg

- Package 1 Width 32 in / 81.28 cm

- Package 1 Gross Weight 2288 lbs / 1038 Kg

- Package 1 Height 61 in / 154.94 cm

- Package 1 Length 50 in / 127 cm