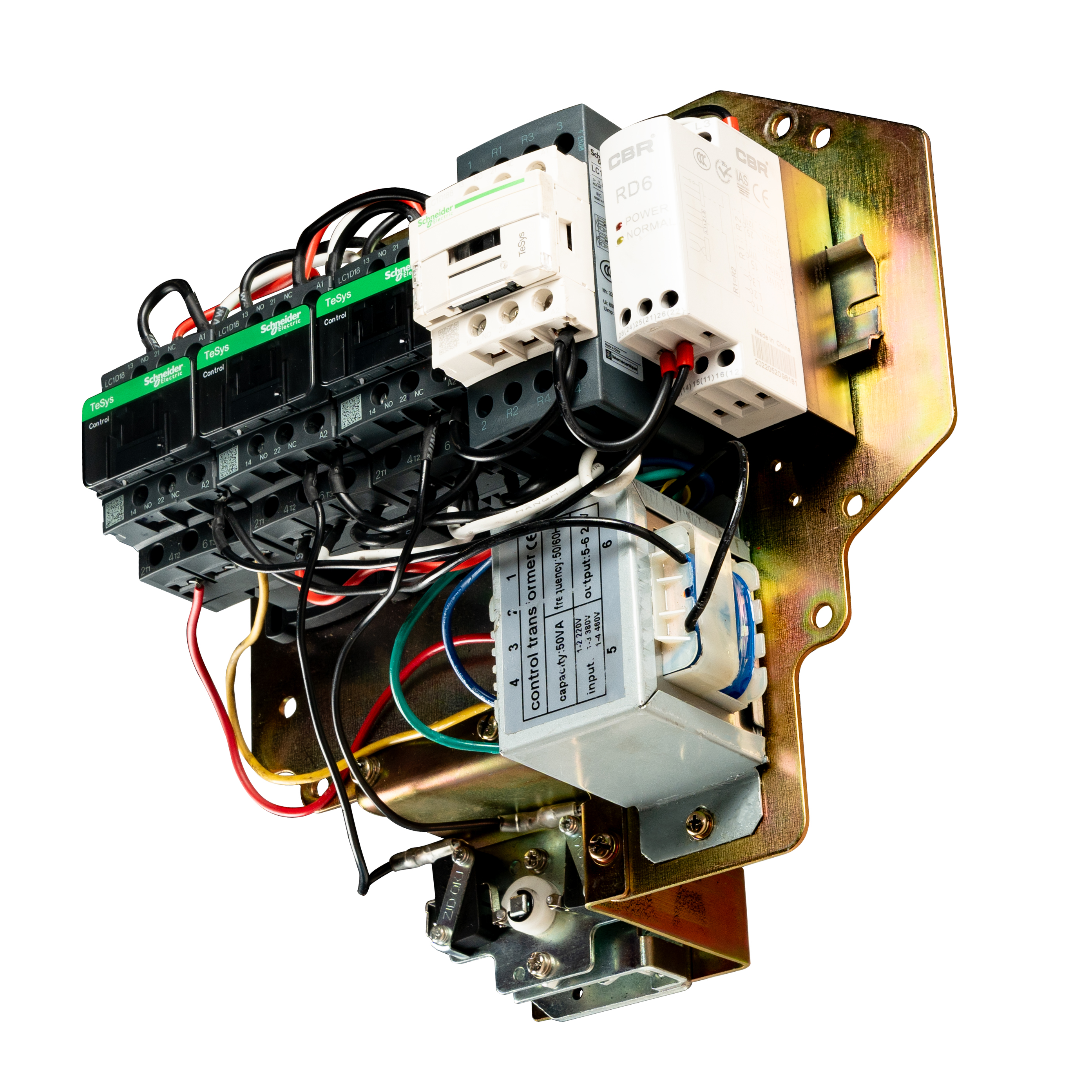

Prowinch is a UL 508A / File No. E524056 Certified Industrial Control Panel (ICPs) manufacturer for United States and Canada with in-house electrical engineers and designers specialized in most types of Cranes, Winches and Hoists controllers offering Complete turnkey solutions and products with multiple optionals to meet applicable UL safety requirements. All our UL508A Control Panels are assembled and tested by Prowinch in our Certified Facility in Miami, USA.

1 ton 2200 lb 208~240/440~480V Electric Chain Hoist Power Trolley 20 ft. FEC G80 Japan Chain H4 Duty

$3,250.19 USD & Free Shipping to commercial locations with dock or forklift

Key features

- Quality is inside: Heavy Duty H4/M5. Aluminum housing, NSK Bearings, USA Chevron Meropa 320 Lub

- US Brand EATON Contactors, All ways Limit Switches, Emergency Stop

- Super Heavy Duty FEC G80 Chain, MADE IN JAPAN. Standard ASTM A973

- US and EC Standards ASME HST-1 , ASME B30.16 , EN14492-2 , EN60204-32

- 3 Year Warranty, Customer Support and Service in the USA

Electric Chain Hoist Description

This M5 1 ton Electric Chain Hoist with Power Trolley allows you to easily lift loads. This hoist comes with an electric trolley that can be quickly installed on an I-beam or crane. The powerful motor and three-phase connection are perfect for use in a wide variety of situations and environments. The quick-connect wiring system allows you get set up and started on your project in no time at all.

Prowinch Electric Chain Hoist with Power Trolley

All of our Electric Chain Hoists are created with the goal of offering the best price–performance ratio. Key components such as lifespan factors are constantly tested and improved in order to offer the best product for the price.Key Components

All internal components have been upgraded to meet the highest quality standards. Key electronic components are produced by American or German brands, and we use American-made lubricants to ensure the lifespan of gears and reducers. Final assembly and all tests are performed in the US before shipping to ensure that every unit meets the corresponding standard.Duty Classification

Duty Classification is a key factor when choosing the right unit. These H4 hoists are suitable for high-volume handling in steel warehouses, machine shops, fabricating plants and mills, and foundries. For uniformly distributed work periods, the hoists have 50% max. operational time per hour and can handle up to 300 starts per hour. When being used for infrequent work periods, the hoist can be operated for 30 minutes from a cold start with up to 300 starts per hour. Operational time ratings are calculated at a 65% load factor, as per ASME HST-1-2012.Control System

This electric chain hoist comes standard with a pendant control. The length of the control is 4 feet less than the lifting height, which allows it to be easily operated from ground-level. An optional wireless control is available for extra convenience.Braking System

The electromagnetic brake system is tested at 125% of the hoist capacity and is designed to automatically engage immediately upon any loss of power.- Rated Load Capacity 2200 lb / 1000 kg

- Emergency Stop Yes

- Standard Lifting Height 20 ft / 6 m

- Contactor EATON 12 AMP

-

Speed (f/m) / min

25ft/7.5m@60Hz

21ft/6.3m@50Hz - Transmission / Reducer Type Spur gearbox with Oil splash lubrication

- Number of Speeds 1 Speed - Optional Variable Speed

- Load Chain Type G80 JAPAN

- Capacity Range 2

- Load Chain Size 7.1 x 21 mm

- Voltage 3 Phase 208~240/440~480V 50/60Hz

- Chain Falls 1

- USA and Canada Voltage 208~240/440~480V

- Chain Length 30 ft / 9 m

- Available Voltages 208~240/440~480V for USA and 380/440~480V for CHILE

- Humidity <85%

- Duty Class H4/M5/2m/Class D

- Temperature -4 ~ 104° F / -20 ~ 40° C

- Motor/Engine Power 1.5 KW

- Trolley Power 0.4 kW

- Motor RPM 1728@60Hz 1440@50HZ

- Noise Level 81 dB

- Motor Brake Yes DC Electromagnetic

- Trolley Speed /min 36 ft / 11 m (Opt. kit 69 ft / 21m)

- Insulation Grade F

- Trolley Number of Speeds 1

- IEC Motor Protection IP55

- I-Beam Width Range 58-153 mm

- Dynamic Brake Only with Optional VFD

- Minimum Turn Radius 2.62 ft / 0.8 m

- Control Pendant Control and Optional Wireless

- Standards Compliance ASME HST-1 , ASME B30.16 , B30.17, EN60204-32

- Control Voltage 24V

- Warranty 3 Year

Unit Weight & Dimensions

- T Trolley Motor Width 6.14 in / 156 mm

- D Depth 13 in / 330 mm

- R Trolley Cover Width 8 in / 200 mm

- W Width 24 in / 620 mm

- H Minimum Headroom 17 in / 430 mm

- J Hook Opening 1.3 in / 34 mm

- Total Unit Weight 213 lbs / 97 Kg

Packaging Weight & Dimensions

- Package 1 Net Weight 213 lbs / 97 Kg

- Package 1 Width 14 in / 35.56 cm

- Package 1 Gross Weight 246 lbs / 112 Kg

- Package 1 Height 33 in / 83.82 cm

- Package 1 Length 28 in / 71.12 cm